Laboratory equipment

- Standards and gauge blocks

- GO/NoGo gauges

- Go/NoGo Plug rings

- Go/NoGo Plug gauge

- Threaded rings Go

- Threaded rings NoGo

- Threaded plugs Go/NoGo

- Pipe cylindrical rings G

- Pipe plug gauge G

- Conical plug gauge R

- Pipe conical rings

- Thread plug gauge UNС Go/NoGo

- Thread plug gauge UNF Go/NoGo

- Thread ring gauge UNC Go

- Thread ring gauge UNC No Go

- Thread ring gauge UNF Go

- Thread ring gauge UNF NO Go

- Threaded rings BSW Go/NoGo

- Threaded plug BSW Go/NoGo

- Threaded rings BSF Go/NoGo

- Threaded plug BSF Go/NoGo

- Trapezoidal threaded rings TR Go/NoGo

- Trapezoidal threaded plugs TR GO/NoGO

- Threaded rings UNЕF Go/NoGo

- Threaded plug UNЕF Go/NoGo

- Tubular conical NPT rings GO/NoGO

- Tubular conical NPT Threaded plug GO/NoGo

- Threaded rings G Go/NoGo

- Threaded plug G Go/NoGo

- Tubular conical R rings GO/NoGO

- Tubular conical R Threaded plug GO/NoGo

- Tubular Pg rings GO/NoGO

- Tubular Pg Threaded plug GO/NoGo

- Measuring bracket

- Special thread gauges SP

- Gage blocks

- Sets of cylindrical measures

- Measuring dart

- Optical flat

- GO/NoGo gauges

- Microscopes, optical instruments

- 3d Measurements

- Impression mass for non-destructive testing

- Hardness tester

- Horizontal measuring machine

- Force gauge

- Profile and Rouphness

- Calibration stands

- Metallographic equipment

- Form control

- Scales, counters

- Probes & displays

- Custom measuring equipment

- Surface plate and straight edge

Laboratory equipment MICROTECH® is divided into general laboratory, measuring, specialty, testing and analytical equipment. Below you can find different measuring equipment for laboratories from MICROTECH®.

Since 2005, the mass production of the European range of laboratory equipment in the ISO 9001:2000 (since 2010 - re-accreditation ISO 9001:20...

Laboratory equipment MICROTECH® is divided into general laboratory, measuring, specialty, testing and analytical equipment. Below you can find different measuring equipment for laboratories from MICROTECH®.

Since 2005, the mass production of the European range of laboratory equipment in the ISO 9001:2000 (since 2010 - re-accreditation ISO 9001:2008) quality system.

Laboratory equipment There are 133 products.

Subcategories

Standards and gauge blocks

TRC, FMS Steinmeyer, Koba, FerTer, Mahr.

Microscopes, optical instruments

MICROTECH offers in Ukraine digital video microscopes Sylvac, Mahr, Baty, supplied with Aberlink or Sylvac software for comparison and work with CAD models. Motorized video microscopes are available with automatic operating modes and a contact edge finder to improve measurement accuracy.

Optical microscopes by Mahr (Germany) are also offered.The MICROTECH enterprise, based on the production workshop of precision mechanics and optics, assembles metallographic microscopes (stationary laboratory or field).

All MICROTECH metallographic microscopes can be equipped with digital cameras up to 38 megapixels with analytical software for image analysis, calculations and logging of the information obtained. Each type of microscope has a portable version for use in the field or on the shop floor.

MICROTECH always has in stock more than 20 types of microscopes and a wide selection of accessories for upgrading and repairing microscopes.3d Measurements

MICROTECH does complex 3D measurements easy and budget due to cooperation with the largest British manufacturer of coordinate measuring machines Aberlink and Swiss manufacturer of measuring arms "Trimos".

The main benefits of Aberlink's co-ordinate measuring machines (CMMs) are intuitive software, affordable pricing (from €19700), Renishaw probe head and stylus set, an industrial PC and English software - all at a basic cost of a co-ordinate measuring machine. MICROTECH provides warranty, service and training.

Aberlink also has a range of compact Xtreme automatic uncompressed machines that can easily be moved between workshops and laboratories.

The Trimos 3D measuring arms (up to 9 metres) use intuitive software from Aberlink. They are used to quickly and accurately measure large-size parts in shop floor environments.

All types of coordinate measuring machines and 3D arms are always available in MICROTECH. We invite you to trial measurements with your parts for FREE.Impression mass for non-destructive testing

Hardness tester

Hardness is a property of a material that characterizes the resistance of local plastic

deformation that occurs when a more solid body (indenter) is introduced into this material.

Hardness is measured by hardness testers that are classified by standards (ISO and ASTM)

according to methods for determining hardness readings:

1. ROCKWELL HARDNESS TESTERS measuring hardness measure the residual

increment in the depth of the tip after unloading:

- on a scale HRA - control of superhard alloys by the indenter "diamond cone",

- on a scale HRB - control of materials of medium hardness by an indenter "steel ball",

- on a scale HRC - control of hardened and tempered parts, indenter "diamond cone".

2. BRINELL HARDNESS TESTERS (HB, HBW scales) according to the indentation

diameter control the hardness of non-hardened steel, cast iron, non-ferrous metals, soft bearing

alloys by means of a steel carbide ball with a diameter from 1.0 to 10.0 mm.

3. VIKKERS HARDNESS TESTERS (HV scale) along the diagonal of the print of the

diamond pyramid control the hardness of small products, thin materials, coatings and films.

4. SHORE HARDNESS TESTERS (HSD scale) determine the hardness of the rolling rolls

by the height of the rebound of the striker, and the Shore hardness meter (scales HA, HD, HC)

determines the hardness of rubber, polymers and porous materials by introducing an indenter into

the surface of the material.

5. PORTABLE T HARDNESS TESTERS measure the hardness of ferrous, non-ferrous

metals, stainless and low alloy steels, using the direct method of the Lieb scale (HL) with the

conversion of hardness values to the values of the corresponding standard scales of Rockwell

(HR), Brinell (HB), Vickers (HV) and Shore ( HSD).

You can calibrate in a NAAU accredited laboratory "MICROTECH" in accordance with the

requirements of the standard ISO 17025-17, while "MICROTECH" performs service and repair of

hardness testers with their subsequent calibration.Horizontal measuring machine

Swiss horizontal Trimos long-lengths for high-precision measurement of parts up to 2000mm and calibration of gauges, plugs, measuring instruments (calipers, micrometers, calipers, indicator and micrometer indicators, length measures).

There are workshop, laboratory versions of long meters with a resolution of up to 1 nanometer.

They are equipped with PCs with metrological control software.Force gauge

MICROTECH® torque wrenches designed to measure and control the torque of a force when tightening both right and left threaded connections.

Scale torque wrenches, designed to measure the torque of a force, are available with a pointer (КМДИ) and digital (КМДЦ) indication. КМДИ keys are distinguished by rather high accuracy for this type of keys and the possibility of fixing the measurement after unloading.

КМДЦ keys are high-precision devices, which, in addition to the main purpose, can be used as part of the standard measuring complexes of the second category. These keys have the ability to work in the alarm mode to achieve the required value of the torque force, as well as the standard RS-232 interface for communication with a PC.

The limit torque wrenches MICROTECH® (КМДП) are designed to control the torque of the force when tightening threaded connections with the right thread. The reference torque of the force is set according to the vernier applied to the key handle drum. The keys are distinguished by increased accuracy (up to 5%), as well as ease of operation and maintainability.Profile and Rouphness

MICROTECH offers portable and laboratory devices for measuring surface profile and roughness:

MICROTECH OSHP roughness samples for visual evaluation of surface roughness

HANDYSURF and SURFCOM TOUCH profilometers manufactured by ACCRETECH (Japan)

Laboratory and portable MarSurf profilometers manufactured by MAHR (Germany).

Stationary profilometers Surfcom Nex for profile and roughness measurement manufactured by ACCRETECH (Japan)

Stationary laboratory profilometers MarSurf for profile and roughness measurement manufactured by MAHR (Germany).

Non-contact nano-profilometers Trimos (Switzerland)

All profilometers, profilometer profilographs, macro-profile meters, sets of roughness measures undergo 100% metrological control in the accredited ISO17025 metrology laboratory MICROTECH .

MICROTECH provides warranty and post-warranty service.Calibration stands

MICROTECH offers stands for calibrating digital and analog indicators, calipers, rulers, tape measures and stands for special tasks produced by Kharkiv MICROTECH and European manufacturers Sylvac, FMS-Steinmeyer.

Indicator stands are divided into manual, semi-automatic and automatic with an optical indicator control system. The discreteness of the stand can reach 0.01 microns.

MICROTECH custom-made manufactures specialized stands for monitoring the geometrical parameters of ceramic tiles and stone slabs, macro profiles.Metallographic equipment

Metallography is a method of examination and control of metals, the preparation and study of the structure of the thin sections in a metallographic microscope. The structure of the studied sample is revealed by etching, or cutting, grinding and polishing the sample. Sample preparation is one of the first steps for metallography and is extremely important in metallography. Quality sample preparation will have a positive effect on the final results of metallography. A lot depends on the quality of sample preparation equipment, e.g. repeatability of material properties from sample to sample.

MICROTECH® grinding and polishing machines are designed for grinding and polishing samples during metallographic studies.

Sample cutting machines are designed for cutting samples during metallographic studies.Form control

Shape deviation - deviation of a real surface from a geometric or nominal one. The surface roughness is not taken into account. Modern measuring instruments (СИТ) for controlling the shape can use the contact method (round gauges, bienimers) and the non-contact method (optical machine for controlling the shape).Scales, counters

For modernization of old machines, microscopes, IZM linear scales WTA and WTV which are linear converters of mechanical movements in an electric signal are applied. The sensitive element captures the mutual movement of the movable and immovable parts of the scale.

The readings transmitted by the scales are displayed using the digital reading units WE-6800 and WE-100. Information from digital reading units can be transmitted to a PC.

MICROTECH® at the request of the customer makes installation of BCI and linear scales, the state certification (if necessary).

You can download INSTRUMENTAL BULLETIN: Modernization MICROTECH®Probes & displays

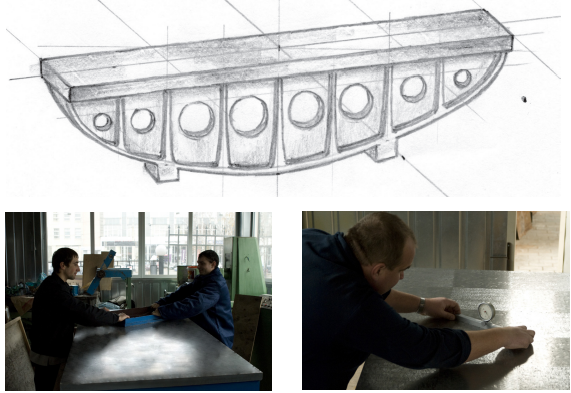

Custom measuring equipment

MICROTECH developing and manufacturing measuring stands for special measurings:- stand for ceramic stones and tiles control

- stand for pipe straightness control

- stand for bottle form control

- stand for 2D macro profile control

Stands equipped with precision multifunctional computerized measuring system with Wireless data transfer.

It’s possible to develop special stands for custom requests and measurings.Surface plate and straight edge

Shape deviation is the deviation of a real surface from a geometric or nominal one. The surface roughness is not taken into account.

To determine the deviation of the shape of flat surfaces most often use the mechanical method, which uses the following FTA: - test lines SP, SD, CMM, UT (rectangular, I-beam, bridges, triangular) of steel and granite up to 8000 mm. 0, 1 and 2; - Plates testing, granite and steel, the sizes to 6000 mm kl.00, 0 and 1; - Rulers local LD, LT, LC (with a bilateral bevel, triangular, quadrilateral) kl.00, 0 and 1; - Precision impression-molding materials.

Kharkiv Microtech ® produces in Europe the most complete range of rulers and calibration plates (including lightweight and granite) in the ISO9001: 2008 quality system at the absolutely best price thanks to Kharkiv grinding and calibration